Leading the world in continuous innovation of fastener insertion technology.

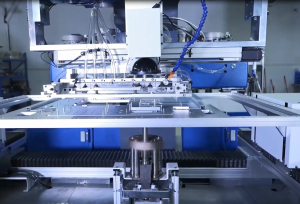

The New E824-4 XYZ-R Servo Insertion Center Main Function

-

Zero errors in your hardware insertion process.

-

Easy setup and programming in less than 15 minutes per new setun.

-

Insertion into sheets up to 32″ x 24″ (800mm x 600mm) from 2 sides.

-

Unmanned production time of up to 8 hours depending on workpiece sizes.

-

Offline software & importing to CAD drawings.

-

Prevent wrong insertion and missed insertion, insert four different type fasteners at once.

-

Fastener/Fastener workpiece hole missing system, will detect and automatically remove the wrong length studs or standoffs.

-

Alignment of the workpiece on the Auto-Load table.

-

Movable workbench.

-

4station automatic change.

-

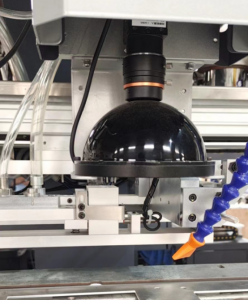

Highly Sensitive CCD Compensation System. Determine whether the hole position of the workpiece is accurate through camera and compensate for the error.

The New E824-4 XYZ-R Servo Insertion Center is Idea for :

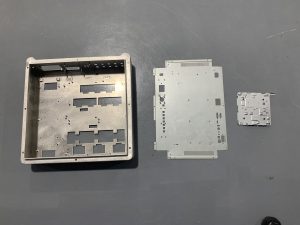

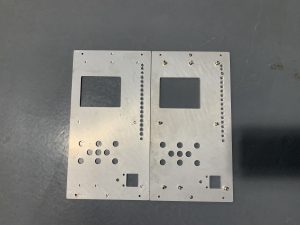

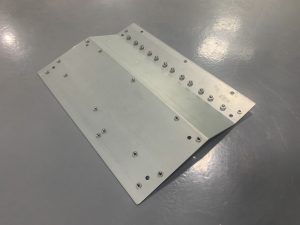

- Flat, single, large workpieces with fasteners required in both sides of the workpiece.

- Multiple, at workpiece with a variety of up to 6 different fasteners.

- Cell environment setup to work simultaneously with 1 operator in combination with a manual insertion machine or press brake.

Specification

| Model | E824-4 XYZ-R |

| Force Range | Adjustable 50 kg/111 Ibs (0.5 kN) to 8000 kg/17, 637 Ibs (80 kN) |

| Throat Depth | 600mm |

| Repreatability | ±0.01mm |

| Fastener Range | M3-M8 Carbon Steel |

| Max Rivet Length | 25mm |

| Speed | 5s/piece |

| Workpiece Range | 800*600mm |

| Max. Workpiece Weight | 40KG |

| Bending Max Avoidance Height | 60mm |

| Workpiece Surface Max Height Difference | 30mm |

| Power | 11.5KW |

| Voltage | 380V/3P/50Hz |

| Machine Size | 3500*2400*2550mm |

| Weight | 2300KG |

Application