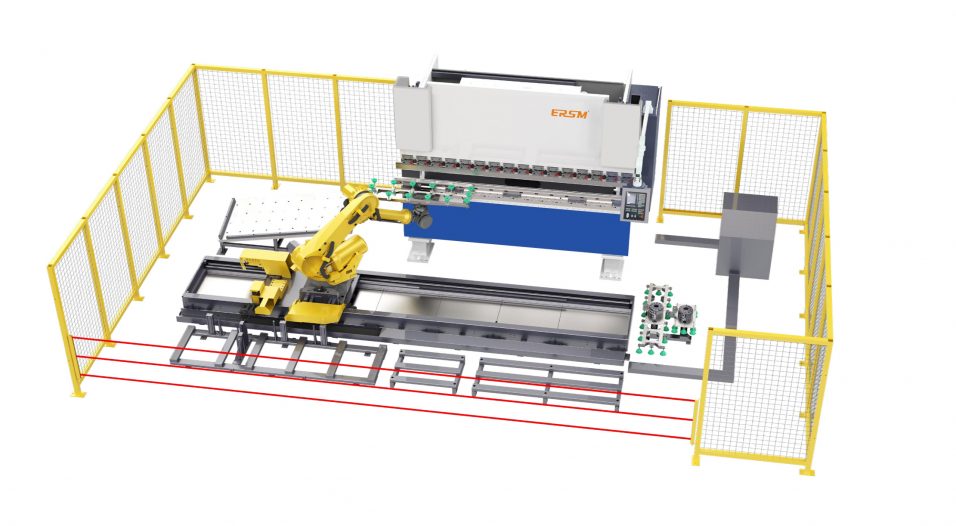

The mobile robot bending flexible processing cell combines the CNC press brake and the robot organically through the PLC motion control system, which can realize the automatic grabbing, centering, bending and stacking of the sheet, effectively reducing the labor cost of manual operation. Labor intensity, and significantly improve productione fficiency, greatly saving costs. According to the bending process of the customer’s workpiece, the bending cell scheme can be customized to meet the customer’s needs to the great estextent.

Specification

| Parameter – Movable Robot Bending Cell | ||||||

| Model | MBC-12 | MBC-25 | MBC-80 | MBC-165 | MBC-210 | MBC-270 |

| Max. Plate Weight | 5KG | 10KG | 40KG | 80KG | 110KG | 130KG |

| Max. Plate Size | 500*500mm | 1000*800mm | 2500*1250mm | 3000*1500mm | 3000*1500mm | 3500*1500mm |

| Robot Model | M-10iD/12 | M-20iD/25 | ER80-2565-BD | R-2000iC/165F | R-2000iC/210F | R-2000iC/270F |

| Brand | FANUC | FANUC | ESTUN | FANUC | FANUC | FANUC |

| Robot Rated Load | 12KG | 25KG | 80KG | 165KG | 210KG | 270KG |

| Robot Arm Span | 1441mm | 1831mm | 2565mm | 2655mm | 2655mm | 2655mm |

| Walking Axis | 2m | 4m | 6m | 6m | 6m | 6m |

Optional Configuration

Quick Change Device

The robot realizes the automatic replacement of grippers of differentspecifications through the quick change device.

Center Console

The center console uses a touch screen to control the operation of the entire robot bending unit, program start, program pause, program stop, product production quantity setting, operating speed adjustment, etc. The centralconsole can monitor the operating status of the entire robot bending machine, product count, running time, signalstatus, alarm information, etc.

Visual Identification System

Automatically select and call the production programaccording to the raw material. Check whether the rawmaterials are mixed with sheets of other specificationsor check whether the direction of the sheets is placed,and whether the front and back sides are wrong.

Single and Double Sheet Detection Device

Using non-contact sensors, the system is directly controlled. If there is overlapping of sheets, it will automatically alarm and suspend operation.

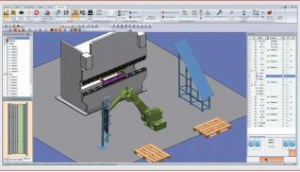

Offline Simulation Programming Software

Fully automatic grabbing of parts and path calculation, interactive grabbing and graphical feedback, manual pathadjustment using control points, simultaneous generationof NC codes for robots and bending machines to ensurecoordinated interaction between robots and press brakefor smooth production.