LM-50 Series CNC Precision 4-high Roller Leveling Machine

Rsm Machinery Co.,Ltd. > Products > Sheet Metal Process Laser Cutting System Blanking Automation > Leveling Machine > LM-50 CNC Series > LM-50 Series CNC Precision 4-high Roller Leveling Machine

4-high CNC Roller Leveler Main Features

- Servo motor to adjust the leveling roller spacing, high precision.

- Semi-automatic & economic type 4-high roller leveling machine, roller gap adjusted by manual in the guidance of digital display, so operator can crank the two hand wheels to adjust leveler’s straightening performance.

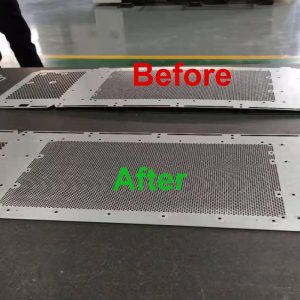

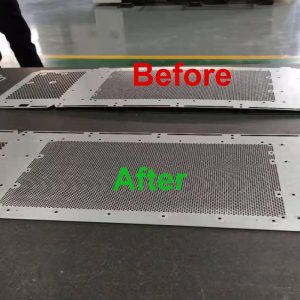

- Suitable for all kind of Steel, Aluminum, copper, stainless steel, mesh sheet, laser cut plate, alloy plate and other metal plate workpiece.

- Suitable for vehicle metal parts, aviation metal parts, high-speed train parts, chain board, saw blade, stamping parts, sheet metal parts, furniture metal parts and electrical appliances parts fabrication etc.

- By balancing internal stress, restoring and improving metal parts flatness, flatness accuracy can reach micron grade, then it can provide qualified work-pieces for next process step of bending, welding etc.

- Roller leveler machine equip with a large number of leveling rollers arranged in multi-layers and a very small spacing between each other, then based on “Bauschinger effect”, sheet metal was repeatedly twisted to make metal fiber gradually consistent, eliminate internal stress, restore and improve the flatness.

- The stagger arranged support rollers ensure leveling rollers bearing heavy pressure in balance without bending deformation, keeping the whole equipment have enough rigidity. Upper and lower support roller column & upper and lower leveling roller group making up four-high layers structure, ensuring stable, efficient and high-quality leveling performance.

- Manual adjust leveling roller gap: At the guidance of digital display, operator can crank the two hand wheels to adjust leveler’s straightening performance.

- 4-high precious leveling machine, there are both support assistant roller set upper and lower leveling roller set. All rollers were well processed to ensure leveling accuracy.

- All leveling rollers adopt high quality bearing steel, finished quenching and tempering, precious machining, hard chrome plating, grinding etc. Surface hardness comes 58±2°(chrome layer thickness ≥0.05mm).

- All backup roller(support roller) adopt Japan export roller bearings. There are 2 columns or more columns backup rollers uniformly distributed upper and lower leveling roller sets, making leveling rollers bears pressure in balance.

- All gears adopt material of 20CrMnTi, finished forging, tempering, surface carburization, precious grinding etc. coming to grade IT6.

- Main bearings are Shielded and sealed NSK bearing made in JAPAN, it can well reserve itself stocked lubrication oil and prevent dust enters, so it doesn’t need to add lubrication oil on bearings.

- Roller gap adjusted by manual in the guidance of digital display, so operator can crank the two hand wheels to adjust leveler’s straightening performance.

- Main power transmission method: AC motor+ speed reducer+ universal joints, so machine runs smoothly.

- High precision and perfect working performance.

Application

- All kinds metal plate work-piece, such as low carbon steel, Aluminum, copper, stainless steel, high tensile steel etc.

- Perforated metal sheet, circle saw blades, clutch parts, lock panels, knives, automobile and motorcycle metal accessories, stamping parts, and electrical metal parts etc.

Specification

| Model |

LM-50-400A |

LM-50-600A |

LM-50-800A |

LM-50-1000A |

LM-50-1300A |

LM-50-1600A |

| Max. Leveling Width |

400mm |

600mm |

800mm |

1000mm |

1300mm |

1600mm |

| Roller Diameter |

50mm |

| Max Plate Thickness |

4mm |

| Leveling Thickness Range |

1.0-4.0mm |

| Min. Workpiece Size |

15*100mm |

| Leveling Speed |

0-12m/min |

| Leveling Roller Quantity |

19pcs(Upper 9pcs/Lower 10pcs) |

| Backup Roller Column |

Both 2 columns up and down |

Both 3 columns up and down |

Both 4 columns up and down |

Both 5 columns up and down |

Both 6 columns up and down |

Both 7 columns up and down |

| Leveling Roller Gap Adjust Method |

Four points auto. Adjust driven by servo motors |

| Voltage |

AC 3 Phase 380V 50HZ(Can customize) |