1,Punching Station

The large punch bed area has a removable front block and is designed to give a very wide range of punching applications. A punch table with rules and guides for repetition work are fitted as standard machine.

2,Section cutting station

The machines are fitted as standard with blades for cutting round and square bars. With extra device, the machines are able to cut, in this aperture, channel, joist, T-section and many other special profiles.

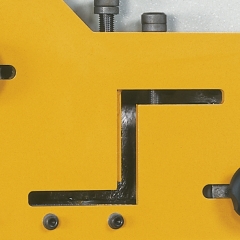

3,Angle station

This station provides large capacity angle cutting at 90° and 45°. Angles between 45° and 90° can be achieved by first cutting at 90° and then flange trimming to the required angle in the shearing station.

4,Shearing Station

The shearing unit is fitted with a simple robust holddown which is adjustable to any thickness of material within the cutting capacity of the machine. The shear feed table with adjustable guides is fitted to allow accurate feeding of materials. The guide can be adjusted to allow mitre cutting up to 45° for flat bars or to trim the flangles of angle.

5,Notching Station

The notching station is fitted as standard with a rectangular notch table with adjustable back stops, allowing repetitive positioning.

The hydraulic circuit is activated by a shielded foot-pedal – the low power inch mode on each workstation enables the correct workpiece-positioning and tool-alignment.

Limit-switches allow accurate adjustment of the stroke length for maximum efficiency. Stroke with automatic return.

Low maintenance

On the cutting station, angle iron can be cut on every angle from 45º up to 90º, both internal and external, without any adaptations to the machine.

Flanges from larger angle-iron can be mitre cut with the shear. Moreover, the machines are equipped with centralised pressure lubrication – being one feature of the low maintenance requirements.

Extensive range of standard machine

The universal steelworkers are delivered with an extensive range of standard device, such as large heavy-duty tables on the punch-, shear-, and notching station. Easy adjustable holddowns to enable production in a safe and accurate way are fitted on every station. Free standing on suitable floor, they just need electrical connection to be ready to work.

| MODEL | COMPACT 40 | COMPACT 45 | COMPACT 60 |

| RATED CAPACITY | 40T | 45T | 46T |

| Punching | |||

| Hole Punching(Diameter x Thickness) | 20X15 | 22×15 | 28×15 |

| Max.Hole Punching(Diameter x Thickness) | 38X8 | 38×8 | 38×11 |

| Stroke | 32 | 50 | 55 |

| Standard depth of throat | 175 | 175 | 220 |

| Extend depth of throat | / | / | / |

| Max. hole size for standard punching | 23 times/minute | 20 times/minute | 26 times/minute |

| Max. hole size for option | 57 | 110 | 110 |

| Max. section steel | 1075 | 940 | 940 |

| SHEARING | |||

| Max. thickness for plate | 200X13 | 200X15 | 200X20 |

| Max. width for plate | 350X6 | 300X12 | 300X15 |

| Cut corner in angle steel, Max. 45 degree | 80X10 | 80X10 | 80X10 |

| ANGLE CUTTING | |||

| 90° | 80X8 | 100X10 | 127X12 |

| 45° | 50X6 | 70X6 | 80X8 |

| SECTION CUTTING | |||

| Round steel/Square steel | 30/25 | 30/30 | 40/35 |

| Channel steel/H steel | 76X38 | 80X45 | 102X51 |

| T steel* | 38X6 | 40X7 | 76X10 |

| NOTCHING | |||

| Plate thickness | 8* | 8 | 10 |

| Width-rectangle | 35* | 35 | 42 |

| Depth-rectangle | 65* | 75 | 100 |

| Depth-V shape | 55* | 60 | 60 |

| Cut edge | – | 80X8 | 100X10 |

| CONER NOTCH | |||

| Max. corner cutting ability | – | 150X3 | 150X4 |

| TUBE NOTCH | |||

| Max. outside diameter for tube | 40 | 60 | 60 |

| flat steel bending | 80X10 | 100X12 | 150X12 |

| plate bending | – | – | – |

| PUNCHING AT NOTCH STATION | |||

| Depth | – | 85 | 110 |

| Max. ability | – | 18X12 | 20X12 |

| TECHNICAL DATA | |||

| Power for main motor | 3 | 3 | 4 |

| Net weight for machine | 550 | 1080 | 1250 |

| Machine size (Length x Width x High cm) | 106X55X48 | 145X59X162 | 152X59X170 |