Safety,Lower Noise,Energy Saving,Affordable All in ERSM

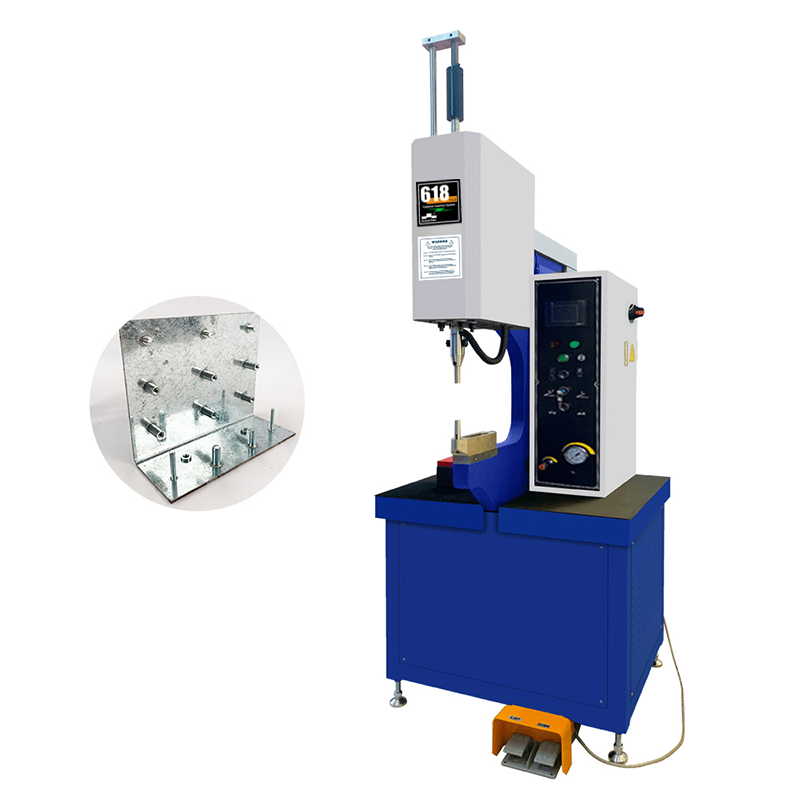

618Plus 6 ton(57KN) ram force, 18 inch(457mm) throat depth, double pump 200mm/s equipped with PLC control system and safety system.

Specification

|

Model

|

618PLUS

|

|

Force

|

2KN – 57KN

|

|

Throat Depth

|

450mm

|

|

Throat Height

|

400mm

|

|

Stroke

|

200mm

|

|

Riveting Capacity

|

M10 nut M8 stud M6 standoff carbon steel

|

|

Main Power

|

1.5KW

|

|

Current

|

4A

|

|

Hydraulic Oil

|

46#/32#

|

|

Oil Tank Reawevoir

|

60L

|

|

Air Pressure

|

0.4-0.6Mpa

|

|

Power Supply

|

380V 3 phase 5 core 50-60HZ

|

|

Package Size

|

36″*43″*78″(930*1100*2000mm)

|

|

Weight

|

650kg

|

Main Functions

- Positive Stop Systey

The system is particularly well suited for improving uniformity on soft, delicate work pieces.

- Batch Counter/Stroke Adjustment

Consists of independent 3 counters. Including workpiece counter, the number of press riveting on a single workpiece and total counter.

- 100% Safety System

Compulsory safety system test with alarm. No security risks. Making the operator to full protection on the conductive and non-conductive work mode.

- Easy Operation

Proprietary stress test adjustment button, allowing you to find the right riveting pressure within 10 seconds.

- Energy Save Dual Pump

High ram force repeat accuracy, faster approach stroke and insertion stroke than single pump.ECO energy save mode, without any insertion action, the pump will shut down automatically after 10 minutes.

- Laser Locating

Assist to handle the big workpiece to cover lower tool by laser locating light reference.

Most Popular Options

- TIS-Turret Insertion System

Multiple manual insertion Install up to 4 different fasteners in 1 Single Part Handling.

- Standard Modular Autofeed System(mas)

Including high quality vibration bowl and intelligent digital variable voltage and variable frequency piezoelectric vibration feeder controller.

- Manual Tooling Package [MSTP-33(metric), ISTP-35/49(imperial)]

Including 31pcs/33pcs/47pcs manual tools, 1 J-frame and 1 fixing base, suitable for most size fastener insertion.

Standard Automatic Tooling System(optional)

1.Shuttle nut tooling system

S-M3/M4/M5/M6/M8-0,1,2

2.Automatic bottom feed tooling

S-M3/M4/M5/M6/M8-0,1,2

3.ABFT with part clearance

S-M3/M4/M5/M6/M8-0,1,2

4.Shuttle stud tooling system

FH: M3-6~25mm/M4-8~25mm/M5-10~25mm/M6-10~25mm/M8-15~25mm

5.Shuttle standoff tooling system

SO/BSO: M3-5~25mm/3.5M3-5.8~25mm/M4-9~25mm/3.5M4&M5-8~25mm