Safety, Efficient, Multifunction, Automatic Force Setting…

618 Msp 6 ton (57 KN) ram force , 18 inch(450mm) throat depth. Auto force setting with proportional valve instead of manual pressure valve setting.

Specification

|

Model

|

618MSP

|

|

Force

|

2KN – 57KN

|

|

Throat Depth

|

450mm

|

|

Throat Height

|

400mm

|

|

Stroke

|

200mm

|

|

Riveting Capacity

|

M10 nut M8 stud M6 standoff carbon steel

|

|

Main Power

|

1.5KW

|

|

Current

|

4A

|

|

Hydraulic Oil

|

46#/32#

|

|

Oil Tank Reawevoir

|

60L

|

|

Air Pressure

|

0.4-0.6Mpa

|

|

Power Supply

|

380V 3 phase 5 core 50-60HZ

|

|

Package Size

|

36″*43″*78″(930*1100*2000KG)

|

|

Weight

|

660kg

|

Main Functions

- Positive Stop System

The system is particularly well suited for improving uniformity on soft, delicate work pieces.

- Ergonomics HMI

Operator control pendant adjustable in 2 directions

- Easy and Fast Operation

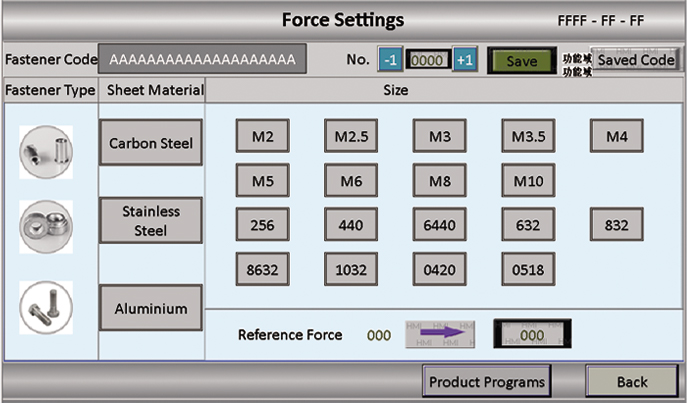

Auto force seeting with proportional all functions one touch seeting

All functions one touch setting

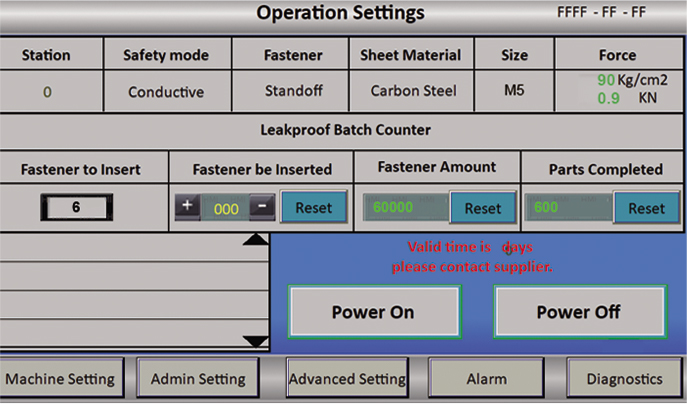

Consist of independent 3counters and a electronic buzzer for audible signals, set and display the number to be insert in the workpiece.

Intuitive I/O open system

- 100% Safety System

Compulsory safety system test with alarm. No security risks. Making the operator to full protection on the conductive and non-conductive work mode.

- Double Side Trunk Base

- Laser Locating

Assist to handle the big workpiece to cover lower tool by laser locating light reference.

- Programs

Up to 200 customized mande fastener database

- Multi Language

Chinese, English, German, Spanish, Italian and Polish

Most Popular Options

- ATIS-Auto Turret Insertion System

Install up to 4 different fasteners in 1 single part handling.It connects with PLC when rotate TIS pressure will change automatically.

- Standard Modular Autofeed System

Including high quality vibration bowl and intelligent digital variable voltage and variable frequency piezoelectric vibration feeder controller.

- Manual Tooling Package

Including 31pcs/33pcs/47pcs manual tools, 1 J-frame and 1 fixing base,suitable for most size fastener insertion.

- Standard Automatic Tooling System(optional)

1.Shuttle nut tooling system

S-M3/M4/M5/M6/M8-0,1,2

2.Automatic bottom feed tooling

S-M3/M4/M5/M6/M8-0,1,2

3.ABFT with part clearance

S-M3/M4/M5/M6/M8-0,1,2

4.Shuttle stud tooling system

FH: M3-6~25mm/M4-8~25mm/M5-10~25mm/M6-10~25mm/M8-15~25mm

5.Shuttle standoff tooling system

SO/BSO: M3-5~25mm/3.5M3-5.8~25mm/M4-9~25mm/3.5M4&M5-8~25mm