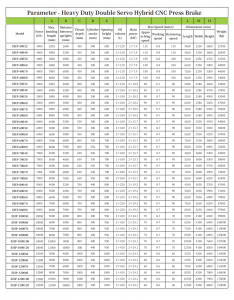

- 400 ton, 500 ton, 600 ton, 700 ton, 800 ton, 1000 ton, 1200 ton.

- RSM machinery takes the lead in applying the dual servo oil-electric hybrid system to the large tonnage CNC press brake, Outstanding energy-saving effect, Stable and reliable mechanical action. Full time computer assisted to ensure the safety and stability of the equipment. Standard confguration of 3+1 axis, Y1-Y2 axis (left and right main cylinder up and down),X axis (backgauge front and back), W axis (mechanical compensation table).

Specification

Main Features

Dual-Servo oil-electric Hybrid Hydraulic System

Mechanical Compensation Workbench

The CNC system controls the mechanical compensation table to ensure high-quality bending accuracy.

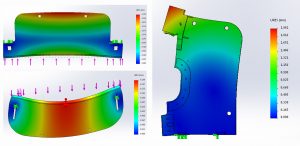

High Rigidity Frame

Frame: frame structure, composed of workbench vertical board, left and right side boards, connecting beams, mechanical compensation device, etc. The steel plate is integrally welded, and the internal stress is eliminated by high temperature annealing and other processes.

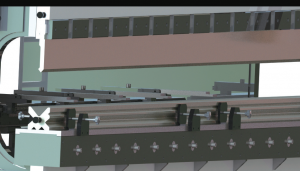

Bending Toll & Fast Clamping

The die consists of two parts, the punch die and the lower die, which are integrally quenched and durable. The punch die is installed on the upper beam and fixed by the heavy-duty clamping device. The lower die adopts the form of a square die, which is convenient and quick to change.

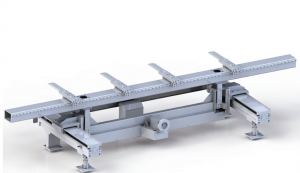

Front Support System (Standard)

According to the length of the workpiece, the supporting bracket can be manually moved to the appropriate position for fastening, and the supporting bracket can be adjusted in the horizontal and vertical directions.

High Precision Grating Ruler

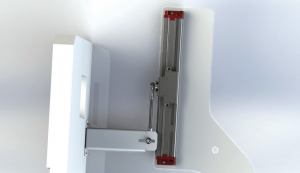

Back Gauge System

Servo-motor driven ball screw, has characteristic of high speed and high setting accuracy. Design of multi stage stops, to increase the positioning range, above the price invalue. Building block design, number of control axIs are available from single-axis X to multi-axis.

HMI Operation Interface

-

Our Factory