Product Features

- Suitable for a variety of bending material (carbon steel, 304 stainless steel, 201 stainless steel, aluminum plate, coated sheet, etc.)

- Full servo control, low energy consumption. Servo-based torque feedback system.

- Muliti-axis linkage control, with a high degree of automation.

- Various feeding and discharging methods (Labour, Robotic arm, Gantry robot, Conveying platform, etc.)

- C-type pressure arm, lead screw multi-link transmission mechanism, pressure adjustment system.

- Easy programming. Operator can customize the design and control of complex sheets according to their needs.

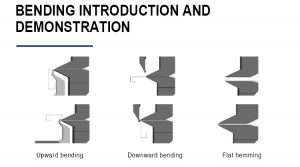

- Flatten hem instructions, press the edge up or down. Arc command, only need input the radius to realize the bending of the arc.

- Three-axis fully automatic positioning system. Multiple positioning.

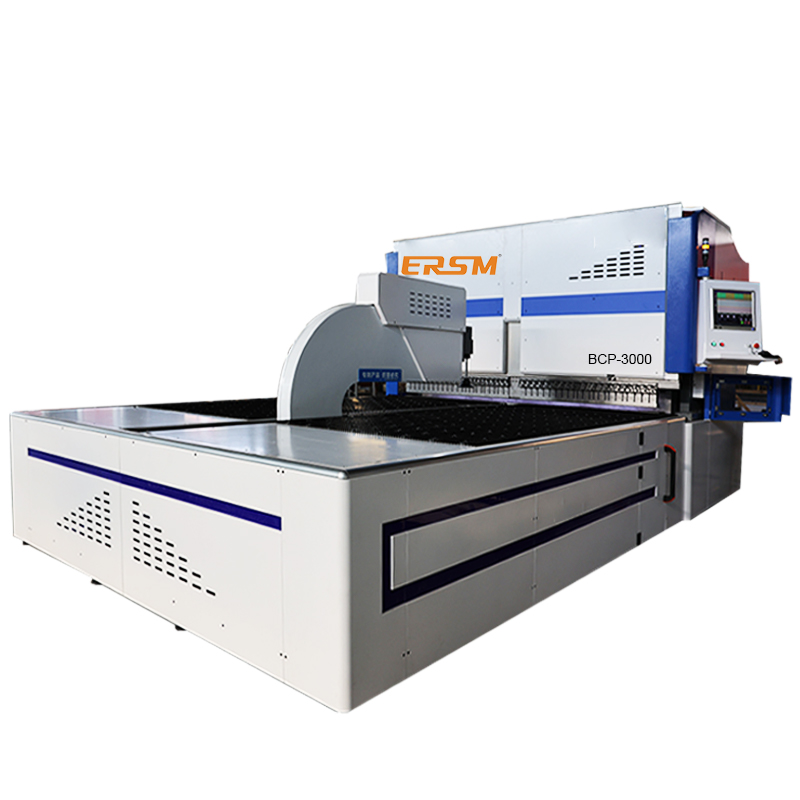

Specification

|

Model

|

BCP-3000-2.0

|

|

|

Feeding Structure

|

Pressure arm type

|

|

|

Max. Bending Length

|

3000mm

|

|

|

Max. Bending Size

|

3000*1250mm

|

|

|

Axis

|

18

|

|

|

Min. Inner Size of Four-side Bending

|

160*260mm(Customized)

|

|

|

Min. Inner size of One-side Bending

|

160mm(Customized)

|

|

|

Max. Thickness

|

Stainless Steel(SS)

|

1.5mm

|

|

Carbon Steel (MS)

|

2.0mm

|

|

|

Aluminum(AL)

|

3.0mm

|

|

|

Min. Thickness

|

0.3mm

|

|

|

Min. Accuracy

|

0.01mm

|

|

|

Bending Angle

|

-90°-90°, >1.5mm

|

|

|

0°-180°, ≤1.5mm

|

||

|

Max. Bending Speed

|

0.2s

|

|

|

Max. Feeding Speed

|

120m/min

|

|

|

Max. Bending Height

|

110mm

|

|

|

Min. Bending Height

|

8mm

|

|

|

Min. Arc Radius

|

2mm

|

|

|

Rated Voltage

|

380V

|

|

|

Motor Total Power

|

115KW

|

|

|

Average Power

|

10KW

|

|

|

Noise

|

55dB

|

|

|

Size

|

6900*4300*2800mm

|

|

|

Weight

|

35T

|

|

|

Workbench Structure

|

Brush and universal ball

|

|

Application

Rsm Machinery Co.,Ltd.

Press Brake/Panel Bender/Folding Machine/Bending Center

Address: Building L1/L2 No. 119 Shuanghua Road Huaqiao Town Kunshan Jiangsu, China

Tel: 86-512-50339036 Fax: 86-512-50339036

E-mail: market@rsm-machinery.com